Chapter 8

Testing And Validating Perovskite Solar Cells

As with any scientific endeavour, the faults, benefits and behaviour of a study’s focus are determined through testing. So when studying perovskite solar cells, how do researchers test them to ensure they perform as desired? Especially since perovskites are still barely a decade old as a technology (and yet to enter the commercial solar market in any major way), there are not yet specific testing standards or protocols for perovskite cells.

To determine the relative capabilities of a solar cell compared to available data for any other technology, you have to be able to achieve provably high-quality values for specific figures of merit that transcend technologies.

The most common being arguably the most important one, Power Conversion Efficiency (PCE), since that is the figure of merit that is used to showcase how good any solar technology is at being a solar power collector.

Beyond this comparison, there are other figures of merit that can inform how the device in question operates and can inform the pathways toward improved performance or explanations for likely failures as mentioned in a previous section.

Some of these other figures of merit include the following:

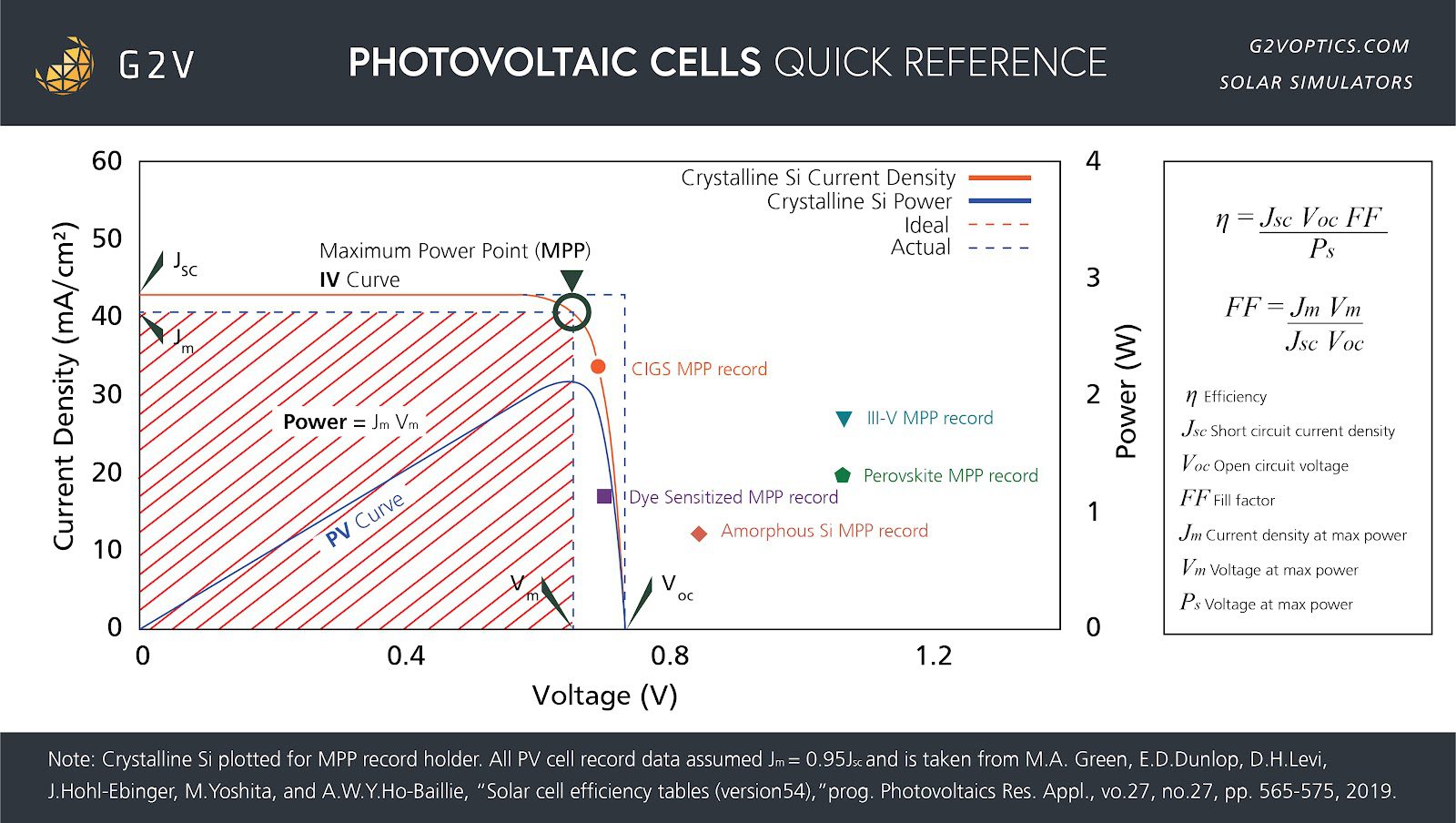

- Short Circuit Current (ISC): This is the amount of current that can be induced to flow through the PV device by incident sunlight when no load is applied to the completed circuit (voltage = 0, resistance = 0)

- Open Circuit Voltage (VOC): This is the voltage that a solar cell experiences when illuminated but without a circuit being completed (current = 0, resistance = infinite)

- The IV Curve: the graphical relationship between the produced voltage and current of a solar cell while operating under illumination at various resistive loads between 0 and infinity

- The Maximum Power Point (MPP): The point on the IV curve where the product of the current and voltage produces the highest value of power

- Fill Factor: the ratio of how close to ideality a certain solar cell is given by the ratio of the MPP divided by the product of the ISC and VOC.

These figures of merit are affected by both internal and external factors for the device in question and thus in order to ensure that the values collected for them are accurate it is necessary to account for these potential influences at all stages of testing.

As shown earlier, perovskites have several potential sources of defects and degradation. These defects and degradation pathways can have detectable effects on the outcomes of any tests for the standard figures of merit needed to make accurate comparisons for the viability of a new solar PV technology.

While the tests for the above-mentioned figures of merit are common across different PV materials and designs, there needs to be either mitigation of specific perovskite defects or testing to identify the primary barriers to achieving desired properties.

Examples of Controlling Variables During Testing: Reducing Temperature For Stable Perovskite Solar Cells And Comparative Standards

Since no solar technology is perfectly efficient there will always be some energy that is unable to be converted to electricity and ends up as heat within the cell itself.

This heat is not only a mechanism for degrading the long-term performance of a perovskite cell but also a reason for the fill factor to diverge from any tested values as heat tends to increase electrical resistance in materials, which pushes the IV curve further away from its ideal shape.

However, since different materials for different types of solar technologies handle the generation, retention, and rejection of heat in significantly varied ways, it is difficult to make comparisons between them at the elevated temperatures that occur during operation.

Different materials have different heat capacities and thus under the same intensity of illumination will have different stable temperatures. To that end, there needs to be a testing mechanism that allows for accurate data collection while managing heat so standard comparisons can be made. Traditionally this has been done with actively cooled substrates but improvements in electronics, detector sensitivities, and sampling resolutions have opened a new option for this.

New Techniques For Perovskite Solar Technology Testing: Flash/Strobe-Based Testing

With the advent of light sources that could be rapidly and repeatedly brought to fully stable operating status within very short periods, the concept of flash testing has arisen.

By pulsing the light source of a solar simulator for between 1 ms to 30 ms, depending on the device design and experimental requirements, it is possible to record reliable responsivity and IV data for a solar cell without any undue heating occurring.

This allows testing to more easily maintain a standard temperature and thereby make temperature-agnostic comparisons of the electrical performance of different solar cells.

Beyond concerns for heat, short-duration light exposure testing also has the ability to give new information that is not easily achievable with continuous-wave solar simulation.

Short-duration phenomena such as charge transport lifespans/recombination timing can be more easily determined by measuring the time it takes for detected current from the cell to reach a chosen baseline after the flash has ceased through a process known as photocurrent decay measurement.

Longevity Testing For Perovskite Solar Cells

When testing solar cells, however, heat is not strictly unwanted.

Temperature is a measure of the amount of motion in an arrangement of atoms and since temperature changes are an inevitable experience in a solar cell’s lifetime, it is thus a major driving force for the long-term degradation of crystalline devices and materials. This is due to thermal motion within crystals displacing atoms from the lattice or causing diffusion of dopants within the crystal lattice. Thus the capability to simulate a long-term operation of a solar panel within a short time is a very useful ability.

By increasing the temperature of the device being tested beyond what would be experienced during normal operations (note: not beyond any temperature that would cause a phase change in the device that would alter the operational characteristics!), it is possible to rapidly “age” a perovskite cell to make educated predictions about the potential lifespans of any device being tested.

This is considered an acceptable method as, barring catastrophic failures, in a fully encapsulated solar cell, heat is the only remaining source of degradation. Therefore, applying more heat (up to certain limits as stated above) is treated as equivalent to a longer time spent at lower temperatures.

Proper longevity testing as shown in the above example is not simply about preventing exposure to sources of defects or degradation, but rather controlling the amount of exposure to highlight the most useful data.

The prescribed figures of merit that are used as comparative standards are useful for judging the viability of a new technology against incumbents and competitors, but varying conditions beyond the standards is how researchers can expose undiscovered flaws or unexpected boons, and ultimately chart paths toward better devices.

The accelerated testing protocols for perovskites are potentially going to require additional experimental design considerations that vary slightly from traditional solar cell technologies in order to collect the same information. This is due to the different material behaviour from one formulation to another.

One of the chief remaining challenges for perovskite researchers is therefore to establish “objective, trusted validation methods that can adequately screen for real-world failure modes.” Some initiatives are working toward that end, such as the Solar Energy Technologies Office (SETO) funding of the Perovskite Photovoltaic Accelerator for Commercializing Technologies (PACT) Validation and Bankability Center.

The hope is that PACT and other researchers’ field and lab testing will ultimately improve understanding and confidence in perovskite real-world durability. The faster that happens, the better, as there are many exciting opportunities for perovskite solar technology to make visible changes to modern life. Read our next chapter, “What Applications Exist for Perovskite Solar Cells in the Near Future?” to get a glimpse at the world of tomorrow.