Chemistry is a complicated subject. Even the most common experiments can have dozens of variables to be cataloged, accounted for, tracked, and controlled. The G2V Pico LED solar simulator has helped Dr. Jesus Adrian Diaz-Real of Cideteq, a public research institute near Querétaro, Mexico, be confident that at least the lighting variable in his work is always under control.

Dr. Diaz’s work has focused on discovering more practical methods and materials for producing photocatalytic reactors. While most of the interest in photocatalysis in the public consciousness is related to producing hydrogen from clean energy sources, chemical applications can extend beyond that single application.

For example, the anode in a hydrogen reactor commonly produces oxygen and similar oxidizing compounds. Highly oxidizing environments near that electrode create a highly chemically active zone that can oxidize many contaminants commonly found in water. This zone gives rise to a second use case, a potential method for water treatment to remove molecular contaminants by reacting them with these oxygen species.

This multivariable experimentation and discovery makes photochemistry an exciting area for Dr. Diaz-Real.

“I was fascinated by the fact that by using just sunlight and oxides that were usually considered inactive and inert, we could drive reactions to generate outputs that can be so [valuable] to people in the forms of clean water and clean energy.”

– Dr. Jesus Adrian Diaz Real

Using a single device to provide several valuable outputs is one avenue for finding a path to commercialization. With a vision of low-cost devices for producing hydrogen and clean water, it is hard not to be excited to see Dr. Diaz’s vision become reality.

Green Hydrogen: Produced from Sunlight and Water

Green Hydrogen is one classification among an entire international system for ranking hydrogen sources by their contributions to global climate change via carbon emissions. Green is the colour associated with carbon-free hydrogen production from water electrolysis via renewable energy sources. While the benefits of a carbon-free source of hydrogen are apparent, there are still difficulties with aligning renewable electricity production with hydrogen production requirements. Thus, Green Hydrogen still has a considerable premium over traditional Grey Hydrogen produced by Steam Methane Reforming (SMR).

Weaning society off fossil fuels requires a solution that can provide a viable alternative for as many applications as possible. While clean electrical energy produced from hydrogen is a valuable way to reduce the reliance on coal or natural gas-produced power, the current primary use of hydrogen is for non-electrical purposes such as ammonia production, feedstock for pharmaceutical manufacturing, petroleum chemistry, and more recently, in direct combustion as a heat source for green steel production. For this and other reasons, finding economical ways of producing green hydrogen can reduce greenhouse gas (GHG) emissions by supporting multiple significant industries with a clean alternative to fossil fuels.

To contribute to this global goal, Dr. Diaz is investigating how to use sunlight more directly to reduce costs and increase the efficiency of green hydrogen production using photocatalytic materials.

There are several components comprising his research. First and foremost would be reducing or eliminating the electricity requirement for hydrogen production. Second, he would ensure this process stays economically viable to promote production at a commercial scale. His last component would be to use this low-cost technology to clean contaminated water.

To understand the great importance of the research Dr. Diaz is working on, we first need to look at the underlying problems Green Hydrogen researchers are facing.

Barriers to Photochemical Hydrogen Production

Inadequacy of Platinum Group Elements for Future Green Hydrogen Evolution at Scale

There are a few obvious methods to reduce costs. Decrease the cost of the input energy, decrease the cost of fabrication, increase the production efficiency, or decrease the costs of any active materials.

Materials currently used in catalytic hydrogen production, usually platinum, palladium, or other platinum group elements or alloys, are costly due to their rarity and demand in other catalytic applications. The scale of these materials needed for green hydrogen production to even simply replace the 87 million tonnes of SMR-produced hydrogen in 2020 would be prohibitive. It would also need to grow to produce about 300+ million tonnes per year to meet our projected global needs in the next decade.

Not only would the cost of producing the necessary amount of traditional catalyst materials be exorbitant, but the difficulty associated with such an increase in production would be an engineering feat by itself.

The Chemistry of Water Splitting and the Balancing of Equations

Given the apparent simplicity of its requirements, water splitting is more complex than one might think. Chemistry is a careful balance; local condition changes such as contaminants, side reaction products, or a build-up of solids or gases on the surface of the electrodes can prevent desired reactions from occurring at the desired rates or even stop them completely. For example, when splitting hydrogen from water, the leftover oxygen produced must be accounted for and prevented from recombining with the now-liberated hydrogen atoms and wasting all the effort put into its evolution.

“When you evolve oxygen, it can be a real problem because it is a very sluggish reaction. Hydrogen is not difficult to evolve, but oxygen is, so [oxygen evolution] is always a bottleneck and improving that reaction gives you the biggest improvements on the whole reaction.”

–Dr. Jesus Adrian Diaz Real

Thus, it takes careful design of electrode materials, surface structure, and operational conditions to make the right products soluble or insoluble at the right places so that an experiment can produce the most of the desired product and as few undesired products or behaviours as possible.

A chemical reaction is a careful balancing act that has to be monitored carefully.

Accurate Data for Improved Photocatalytic Experimentation

When dealing with photon-mediated reactions, where light is a significant fraction or majority of the energy required for a process, a concern arises: excess, uncontrolled, or unwanted energy influences the experiments.

Excess light, particularly infrared light, creates excess heat, which can alter the reaction rate of a reaction or process. In the case of hydrogen evolution, higher temperatures tend to improve production efficiency. While that sounds like good news, it can complicate the proper characterization of a system.

When trying to determine the efficiency of the base process so that it can be optimized, having the results skewed higher than they should be is not beneficial if what is responsible for the higher production cannot be accurately accounted for.

Potential Paths for PEC Hydrogen to Reach Commercialization

Low-Cost Catalytic Materials – Oxides and Nitrides

Dr. Diaz is looking into alternative catalytic materials to replace the traditional platinum group element catalysts. The best alternatives use semiconductive properties to produce the free electrons that promote hydrogen and oxygen evolution from water under exposure to sunlight.

There are several options available: the original UV-sensitive oxide semiconductor, TiO2, the more recently popular Iron (III) Oxide, also known as Hematite, Bismuth Vanadite (BiVO4), Carbon Nitride (C3N4) and Strontium Titanate (SrTiO3).

These materials represent substantial cost savings compared to the platinum groups of traditional research.

Utilizing these materials to convert photons into charge carriers to drive the redox reaction is an efficient way to carry out water splitting. In terrestrial Earth, the majority of incident light occurs in the visible portion of the spectrum (400 nm – 800 nm). Using materials like C4N4, Fe2O3, or other semiconductors capable of taking advantage of these lower-energy photons makes them particularly interesting for hydrogen production in solar photoelectrochemical processes.

Using materials with different band gaps together can create a heterojunction that can cause a photocurrent simply by exposure to sunlight. Taking advantage of this behaviour makes it possible for a system to produce hydrogen and oxygen automatically without any energy input beyond sunlight.

In terms of reducing energy costs, there isn’t anything cheaper than free!

Photocatalytic Reaction Control for Multiple Useful Products

Hydrogen is only half the story.

When splitting water (H2O) to make hydrogen, oxygen is always present as either molecular O2, singlet radicals, or hydroxide (OH) ions or radicals, several of which can contribute to the formation of hydrogen peroxide (H2O2). In fact, using a system that produces hydrogen peroxide instead of O2 boosts hydrogen evolution efficiency as it only requires a 2-electron reaction compared to oxygen, which requires a 4-electron reaction.

Side reactions that produce oxidizing species of molecules aren’t necessarily bad, though.

The molecules mentioned earlier should sound familiar, as we most commonly use them as cleaning agents or as part of sterilization treatments. We use these molecules for these tasks precisely because they are energetic and chemically active, exactly what is needed to break down and remove long-lived, stable chemical contaminants. Dr. Diaz’s research has previously explored the usage of OH° radicals as oxidizing reactants for the degradation of indigo carmine and methylene blue dyes.

To maximize the solar energy utilization of his systems, Dr. Diaz uses different active materials for the anode and cathode with different band gaps to ensure that neither electrode uses the energy the other needs from the available spectrum. With heterojunctions of these hydrogen and oxidizing species producing materials, it is possible that if Dr. Diaz is already producing these molecules that could treat water with excessive amounts of unwanted chemicals, why not pursue improving that outcome simultaneously?

His future research could improve the economics of his devices by producing clean water and hydrogen simultaneously from contaminated water.

A perfect example of the cliche of one man’s trash being another’s treasure.

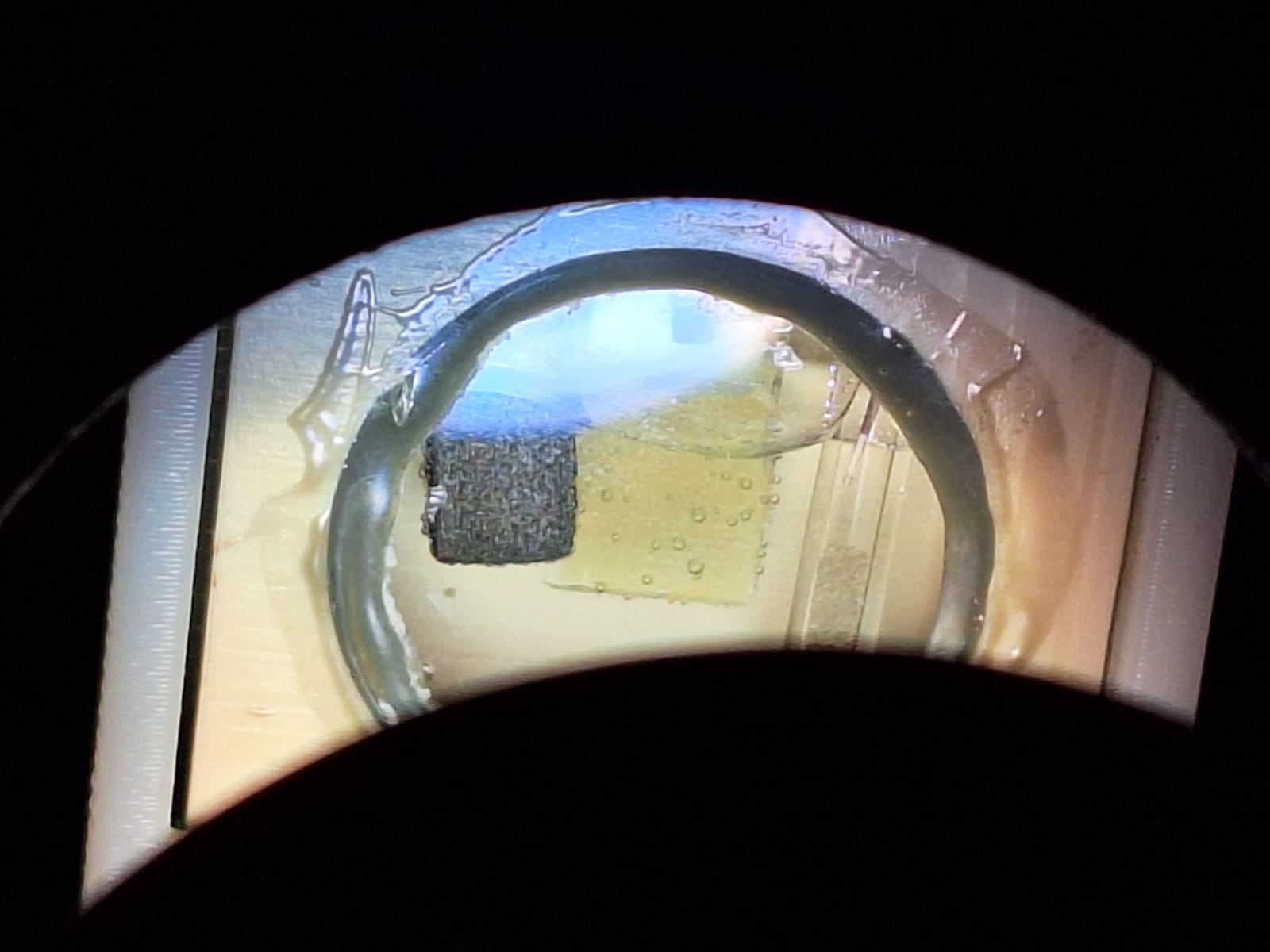

A Premium Light Source for Innovating the Green Hydrogen Revolution

Dr. Diaz required a light source with a well-defined and tunable spectrum to ensure that his current and future experiments would produce the most accurate data possible. This way, he will know exactly how much energy he is exposing his samples to and the impact that different wavelengths have on his samples.

“I’ve had to work with Xenon and Tungsten Halide lamps back in my Ph.D., but the limited lifespan of these devices took up a great deal of time that I wanted to spend on my research… so I tried working with LEDs myself to mix and concentrate the light from several LEDs, [which was very complicated], and this is what your Pico does very reliably for me.”

With his G2V Pico, Dr. Diaz can ensure that the chosen wavelengths of interest drive his reactions. This control gives an accurate baseline to compare against other tests run with extra variables such as higher temperatures, applied voltages, or other potential additional energy sources. Science is a systematic approach to teasing out the behaviours of the natural world, and the more control of any procedure it is possible to have, the more confident everyone can be in the results.

So, with the most controllable light source at his disposal to help characterize his experiments, it is plain to see why Dr. Diaz is so optimistic about his team’s work.

The Plan and the Path

So, how does Dr. Diaz plan to get there from here?

As stated earlier, hydrogen is an almost 100 million tonne per year commodity when considering all its end uses in chemistry, energy, and fertilizer, to name a few. With the push to start replacing carbon-based energy sources for these fields, that amount is predicted to more than triple over the next few decades. So, time is of the essence to find better and more practical methods for producing all that hydrogen.

Iterating and testing as many device materials and architectures as possible is necessary to determine an optimal course of action to increase production. So, Dr. Diaz is using his Pico light source to its utmost advantage. By being able to utilize it in a programmatic method of following self-written Python scripts, Dr. Diaz and his students can load up an entire day’s schedule of testing and automatically collect data from these experiments while being able to pursue other work, vastly improving their time efficiency.

One of Dr. Diaz’s plans is that, thanks to the Pico’s small size, he can place multiple different experimental set-ups around it and use a rotating table to align the Pico with each one according to a scheduled program as another layer of practical automation to improve his lab’s data collection capabilities. So, instead of changing out reagents to run different experiments, he can simply have multiple different formulations ready to go, minimizing downtime and allowing rapid comparison.

It is this kind of ingenuity and systems design thinking that we at G2V are happy to see and facilitate with our devices. We at G2V hope that this kind of insight and creativity will serve Dr. Diaz and his research team well in building a path to a cleaner future for all of us.

“You have to be fascinated by what you do. Without that, you won’t be able to stay right at the edge of knowledge. Generating new knowledge costs a lot, but simply being fascinated by the idea that you can do it helps make everything worth it.”-Dr. Jesus Adrian Diaz Real

References

31st International Materials Research Congress – IMRC 2023. Accessed March 13, 2024. https://www.mrs-mexico.org.mx/imrc2023/

Cardenas-Martinez, Jessica, Thomas Holm, and Jesus Adrian Diaz-Real. “An Aqueous-Based BiVO4 Precursor for Controlled and Enhanced Properties towards Water Splitting.” ECS Meeting Abstracts MA2022-01, no. 45 (July 7, 2022): 1918–1918. https://doi.org/10.1149/ma2022-01451918mtgabs

Collins, Leigh. “A Net-Zero World ‘Would Require 306 Million Tonnes of Green Hydrogen per Year by 2050’: IEA.” Recharge, May 18, 2021. https://www.rechargenews.com/energy-transition/a-net-zero-world-would-require-306-million-tonnes-of-green-hydrogen-per-year-by-2050-iea/2-1-1011920

Córdova-Almeida, Francisco Javier, Darshana Rajput, J.G. Torres-Torres, S. Gallardo- Hernández, Adrián Cervantes-Uribe, Jesús A. Diaz-Real, Srinivas Godavarthi, and Goldie Oza. “SrTiO3/G-C3N4 Mesostructured Heterojunctions for Photocatalytic Evaluation Using Methylene Blue.” Materials Letters 352 (December 2023): 135183. https://doi.org/10.1016/j.matlet.2023.135183

Córdova-Almeida, Francisco Javier, Darshana Rajput, J.G. Torres-Torres, S. Gallardo- Hernández, Adrián Cervantes-Uribe, Jesús A. Diaz-Real, Srinivas Godavarthi, and Goldie Oza. “SrTiO3/G-C3N4 Mesostructured Heterojunctions for Photocatalytic Evaluation Using Methylene Blue.” Materials Letters 352 (December 2023): 135183. https://doi.org/10.1016/j.matlet.2023.135183

Descant, Skip. “The High Cost of Hydrogen Fuel Is a Drag on Adoption.” GovTech, July 17, 2023. https://www.govtech.com/fs/the-high-cost-of-hydrogen-fuel-is-a-drag-on-adoption

Díaz-Real, Jesús A, Geyla C Dubed-Bandomo, Juan Galindo-de-la-Rosa, Luis G Arriaga, Janet Ledesma-García, and Nicolas Alonso-Vante. “Impact of the Anodization Time on the Photocatalytic Activity of TiO2 Nanotubes.” Beilstein Journal of Nanotechnology 9 (October 4, 2018): 2628–43. https://doi.org/10.3762/bjnano.9.244

“The Hydrogen Colour Spectrum.” National Grid Group. Accessed March 13, 2024. https://www.nationalgrid.com/stories/energy-explained/hydrogen-colour-spectrum

“Inicio ” CIDETEQ – Centro de Investigación y Desarrollo Tecnológico En Electroquímica.” CIDETEQ, February 7, 2024. https://www.cideteq.mx/

James, Brian D., George N. Baum, Julie Perez, and Kevin N. Baum. “Technoeconomic Analysis of Photoelectrochemical (PEC) Hydrogen Production.” US Department of Energy, December 2009. https://www.energy.gov/eere/fuelcells/articles/technoeconomic-analysis-photoelectrochemical-pec-hydrogen-production

Kim, Hwapyong, Joo Won Seo, Wookjin Chung, Ghulam Mustafa Narejo, Sung Wook Koo, Ji Su Han, Jiwoong Yang, Jae‐Yup Kim, and Su‐Il In. “Thermal Effect on Photoelectrochemical Water Splitting Toward Highly Solar to Hydrogen Efficiency.” ChemSusChem 16, no. 11 (April 5, 2023). https://doi.org/10.1002/cssc.202202017

Liu, Jiali, Yousheng Zou, Bingjun Jin, Kan Zhang, and Jong Hyeok Park. “Hydrogen Peroxide Production from Solar Water Oxidation.” ACS Energy Letters 4, no. 12 (November 13, 2019): 3018–27. https://doi.org/10.1021/acsenergylett.9b02199

Man, Isabela C., Hai‐Yan Su, Federico Calle‐Vallejo, Heine A. Hansen, José I. Martínez, Nilay G. Inoglu, John Kitchin, Thomas F. Jaramillo, Jens K. Nørskov, and Jan Rossmeisl. “Universality in Oxygen Evolution Electrocatalysis on Oxide Surfaces.” ChemCatChem 3, no. 7 (March 16, 2011): 1159–65. https://doi.org/10.1002/cctc.201000397

Martínez-García, H., D. Salazar-Marín, V. Collins-Martínez, J.G. Torres-Torres, M.K. Kesarla, O.A. Jaramillo-Quintero, N. Hernández-Como, et al. “Rationally Designed C3N4/ Tio2 (Anatase/Brookite) Heterojunction for Enhanced Photocatalytic Hydrogen Generation under Visible Light.” Ceramics International 49, no. 21 (November 2023): 33901–11. https://doi.org/10.1016/j.ceramint.2023.08.084

Perret, Robert. “Solar Thermochemical Hydrogen Production Research (STCH).” US Department of Energy, May 2011. https://www.energy.gov/eere/fuelcells/articles/solar-thermochemical-hydrogen-production-research-stch-thermochemical-cycle

“Photocatalysis Lecture 5: Monochromatic Photocurrent Conversion Efficiency (IPCE).” Perfect light. Accessed March 13, 2024. https://www.perfectlight.com.cn/technology/detail-56.html

Seki, Munetoshi. “Bandgap-Engineered Iron Oxides for Solar Energy Harvesting.” IntechOpen, January 26, 2018. https://www.intechopen.com/chapters/59047