The OSAM-1 Mission at the Goddard Space Flight Center

NASA, the National Aeronautics and Space Administration, is the United States’ civil space program that is so well-known its namesake is freely used in countless science fiction stories and films. What they make possible, however, is far from fiction. Through its 20 centers and facilities, NASA explores, discovers and expands human knowledge, all while generating significant economic output compared to its federal budget. Since its founding in 1958, NASA’s work has resulted in common-place spin-off technologies such as camera phones, scratch-resistant lenses, and baby formula.

One of NASA’s most critical facilities is NASA’s Goddard Space Flight Center, named after the father of modern rocket propulsion and founded early in NASA’s history (1959). The Goddard Space Flight Center houses the United States’ largest group of scientists, engineers and technologists building spacecraft, instruments and technology to study outer space. Located in Greenbelt, Maryland just outside of Washington DC, Goddard is responsible for Hubble operations and the James Webb Space Telescope, as well as managing space communications and seeking answers to the universe’s deepest mysteries, building whatever instruments and technologies are needed along the way.

Its missions have studied the atmosphere of Mars, the activity of the Sun, as well as the state of our own planet’s climate. Each mission is a significant undertaking and involves many years of coordinated effort.

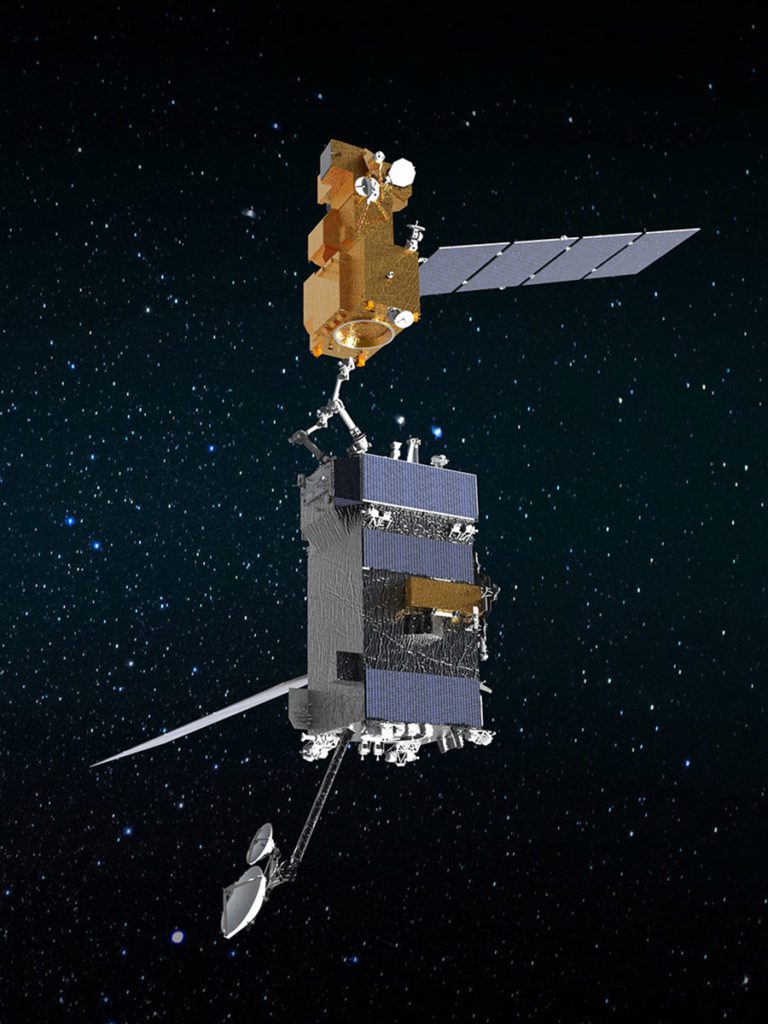

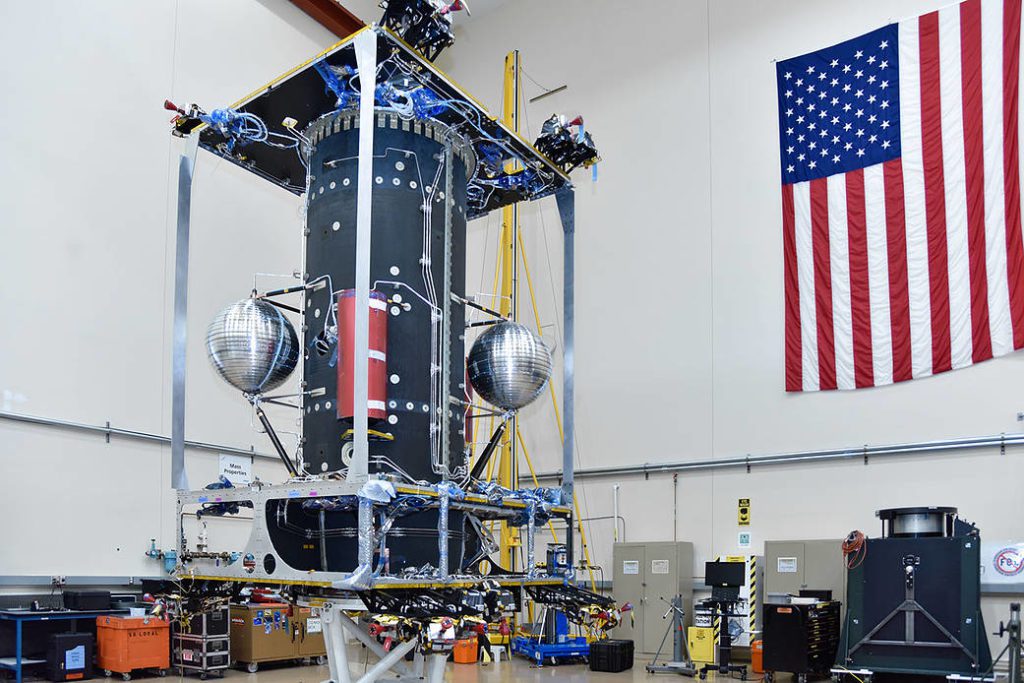

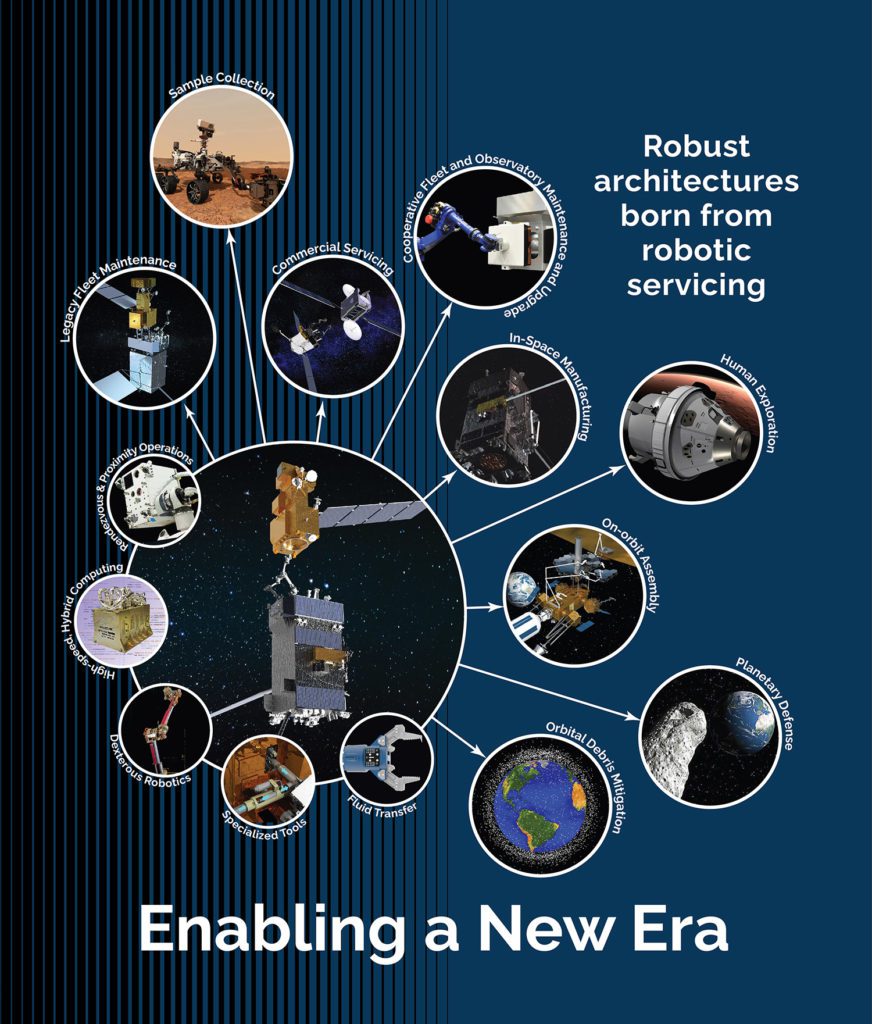

OSAM-1, which stands for On-orbit Servicing, Assembly and Manufacturing, is one such mission. Aiming to develop the technologies needed to increase the life-expectancy of satellites of all kinds (even those not designed for orbital servicing), the OSAM-1 robotic servicer needs to demonstrate that it can successfully capture, refuel, and move a satellite in orbit. In addition to refueling a satellite, OSAM-1 will also assemble a communications antenna and manufacture a beam to demonstrate assembly and manufacturing capabilities. OSAM-1’s launch is scheduled for 2026 which, if successful, is expected to help establish a servicing industry providing more flexibility and efficiency for satellite fleet operators worldwide, which could be beneficial in reducing the growing problem of orbital debris.

Space may seem infinitely, well, spacious, but it’s crowding to the point where space launches might become exceedingly difficult. Orbits continue to gather space junk from nonfunctional spacecraft, abandoned launch vehicle stages, mission-related debris, and fragmentation debris. Add to this orbital debris an increasing number of satellites from SpaceX’s starlink constellations and the expanding CubeSat industry, and you have a situation where a catastrophic cascade effect known as the Kessler Syndrome becomes increasingly likely.

Former NASA scientist Donald Kessler proposed his eponymous idea in a 1978 paper entitled, “Collision Frequency of Artificial Satellites: The Creation of a Debris Belt.” Kessler Syndrome describes how collisions can create orbital debris which increase the likelihood of further collisions and create a growing debris belt that would then impact future spacecraft designs and ultimately hinder humanity’s activities in space. Our activities in space could become the most significant long-term source of debris, far worse than natural meteoroid sources.

The National Academies, after analyzing data from six space agencies, estimates that a catastrophic collision is likely to occur every five to nine years. Technologies such as those developed for the OSAM-1 mission could play a significant role in better managing humanity’s footprint in orbit and reducing the likelihood of such collisions and cascades. They could help mitigate the need for some of the ISS’s 29 debris-avoiding maneuvers between 1999 and 2021. They could allow us to help clean up the roughly 3,000 nonfunctional satellites that remain in orbit.

OSAM-1’s unique client berthing system will first be used to rendezvous with the government-owned Landsat 7 satellite. OSAM-1’s docking approach will be guided by cameras to capture and process images in real-time to create a “pose” of the two satellites’ relative positions. The docking will be done entirely autonomously. After docking, OSAM-1 will “operate” on Landsat 7 with its tools, maintaining a narrow gap of about 1 meter between the two spacecraft. The servicing and refueling aspect of OSAM-1’s mission consists of a lengthy period during which the OSAM-1 and Landsat-7 will be in a berthed configuration with OSAM-1 taking over flight control.

All phases of OSAM-1’s mission are complex and require extensive design and validation. For OSAM-1 to ultimately be successful in its mission to refuel Landsat 7 and demonstrate assembly and manufacturing in space, it must first be tested on the ground.

“You have to test as you fly and fly as you test. We’ve had that drilled into us since the Hubble program.”

The Challenges

One of the primary aspects of the space environment that must be simulated before flight is the irradiance of the Sun. The impact of sunlight might seem trivial compared to the impact of hard radiation and extreme temperature swings in a vacuum. However, for some missions, the effect of sunlight can be critical in determining success or failure.

One past mission where sunlight was initially overlooked was RRM Phase 1 (Robotic Refueling Mission). Operators needed to remotely control the Canadian Dextre robot to use four tools to do tasks such as opening fuel valves and transferring liquid through a hose. For the first phase of RRM, the intention was for Dextre to grab a box of approximately 1 m3, perform some work on that box, and then pull away.

When NASA operators flipped on the RRM module lights with the Sun in the background, however, their vision went white. Either their lighting system or the Sun had sent a reflection into the visualizing camera, effectively blinding the operators from what was going on.

NASA clearly wants to avoid this issue on future missions. For OSAM-1, the original mission plan was to operate in what’s called an “eclipse” — i.e. with no sun shining on it. The team would have 20 minutes in every 90-minute orbital period during which they could perform operations in the dark. Some of the robot’s tasks could be done autonomously during the 70 minutes of ensuing sunlight.

That was the original concept several years ago, when OSAM-1 was known as Restore-L. However, the mission’s scope was expanded (which prompted the name change), and the December 2020 launch date was pushed back to 2026.

Unfortunately, the Landsat 7 satellite client’s orbit is degrading and drifting away from its polar low-earth science orbit. This degradation will continue until the OSAM-1 rendezvous. In 2026, Landsat 7’s orbit will have changed such that the entire period will be in full sunlight. Once the team realized they’d be operating in sunlight, they knew they had to test with a solar simulator to avoid running into issues similar to those encountered in RRM Phase 1.

The team would need two large area solar simulators to fully test different aspects of the mission. OSAM-1’s docking approach to LandSat-7 will be guided by cameras. On the ground, the OSAM-1 team has a full-scale mockup of the Landsat 7 satellite They would need the first solar simulator to illuminate the entire setup to predict what OSAM-1’s cameras will see, and accurately rehearse the entire docking operation.

The second solar simulator would be used for a second phase of the mission, when the OSAM-1 is “operating” on Landsat 7 over a 1 meter gap. In this configuration, the sunlight coming in from the side will create a unique lighting environment that will need to be appropriately simulated to enable a full rehearsal of the operation.

Because the two phases have substantially different configurations, the same solar simulator cannot be used for both. The testbed team at NASA Goddard therefore set out to procure two large-area, precise solar simulators.

Large Light from a Small Area

The OSAM-1 team needed to illuminate a large area, roughly a 14-foot long bus, to match the Landsat 7 dimensions. The artificial solar illumination needed to be uniform in intensity, such that there was minimal variation in irradiance across the illumination plane: specifically, they needed the irradiance to remain within a tight specification over the target area.

The easiest optical strategy to achieve a uniform intensity is to have light sources much larger than the target area. However, the dimensions of the satellite were already quite large, so having a solar simulator that was multiples of the Landsat 7 dimensions would not only be prohibitively expensive, but introduce significant mechanical challenges for hoisting and maneuvering the arrays into their various configurations around the test area.

Therefore, the first challenging specification the OSAM-1 team required was to minimize the ratio of the size of the light array compared to the size of the uniformly illuminated area. By achieving this specification, a solar simulator solution would be able to reasonably fit within their allotted volume for the testbed work.

Low Divergence Angle

The second key specification for a solar simulation solution was a low divergence angle. The angular content of sunlight is mostly collimated (i.e. the light rays are parallel) because of the vast distance the rays have to travel to reach our planet. Because surface reflections off all the various pieces of the spacecraft depend so strongly on incident angle, the OSAM-1 team wanted to ensure they got a light source that would adequately replicate those reflections so they would know the circumstances under which their camera might get saturated or “whited out” by a stray reflection. If they had a solar simulator with a wide range of emission angles, then the reflections would not only be dimmer but the geometries under which they’d occur would be significantly different. Finally, their camera’s acceptance angles would introduce more complications ultimately calling into question the validity of testing if they didn’t have a low-divergence solar simulator.

Match Camera Spectral Responsivity

The OSAM-1’s visible camera has three channels, one each for red, green and blue (RGB). The team needed to ensure that their camera channels were accurately characterized for the expected spectrum in outer space (AM0), so they could ensure they’d be able to visualize the docking maneuvers under the full dynamic range of expected light. They therefore needed a solar simulator that could adequately reproduce the expected spectrum and power (AM0) for the spectral response of their detector.

Minimize Thermal Load

All of OSAM-1’s intended testbed work needed to occur inside a clean room, an environment where making changes to the existing HVAC infrastructure can be considerably expensive. The many-kilowatts of electrical power they would need for any solar simulator were one concern, and closely related were the overall efficiency and thermal dissipation of the light source. At these high levels of power consumption for large light arrays, the efficiency of the light sources matters a great deal in determining the follow-on degrees of thermal management required to keep everything at stable temperatures.

“My experience with solar simulators is that we usually end up with a lot of heat and power that we have to deal with.”

The OSAM-1 team therefore needed a solar simulator solution that would minimize both power consumption and the required thermal management infrastructure.

Reduced Cost

Finally, an implied restriction on this aspect of the OSAM-1 project was to keep the cost as low as possible. Not only was the project government-funded through NASA’s federal budget, but the requirement for solar simulation was introduced at a late stage in the OSAM-1 project’s trajectory (after the launch date was pushed back). Therefore, while the OSAM-1 team didn’t want to compromise on the quality of their solar simulator, they also didn’t want to overspend and exceed their remaining budget.

The Solutions

The OSAM-1 team began market research of light source providers, looking at everything from component suppliers to stadium lighting installers.

“We looked at [xenon] arc lamp sources, but very quickly established that an array of smaller LED sources could deliver the best solution considering volume, mass and power constraints.

G2V had an existing solar simulator line that could meet our needs, a firm understanding of what we desired, and the engineering expertise in-house to convincingly verify all technical requirements.”

“G2V is one of the companies that stood out as having the products and in-house systems engineering able to provide customized lighting solutions that could meet our requirements.”

After diligent research, NASA selected G2V as the contractor for their solar simulators, for many technical reasons we’ll discuss below. Overall, G2V was uniquely positioned with the expertise to build a solution for NASA by combining two existing product lines.

“I love working with [G2V]. [They] have been extremely responsive as a vendor. We’re not waiting weeks to get an answer; we’re getting our answers in hours or a day.”

Multi-source Solar Simulator to Minimize Footprint and Divergence

Traditional gas-discharge-lamp sources, such as xenon arc and metal-halide, typically use a single high-powered bulb to produce illumination. In order to achieve a uniform beam under these circumstances, the easiest approach is to have a very large illumination area, and only use a small subset as the uniform area. Once you add a few bulbs (which would likely have been required for this application), the strategy is even more necessary since collimating optics don’t effectively combine light sources unless you have many of them closely-packed.

Having such large-bulb sources also means very large, and very expensive collimating optics to try and control the angular spread. Therefore, to hit the target illumination area AND the low divergence requirements, a traditional gas-discharge-lamp would have been very large and very costly.

G2V’s solution uses a proprietary Engineered Sunlight® technology based on light-emitting diodes. This technology can be software controlled and more easily shaped into a uniform irradiance field, without requiring the light array to be significantly larger than the desired uniform beam area. For smaller light sources, collimating optics are also significantly cheaper, thus making it possible to achieve a reasonable size of solar simulator while minimizing costs. G2V’s proposed solution to NASA was not only technically superior, but also more within budget.

Efficient LED technology to Minimize Heat Load

The wall-plug efficiency of LEDs is much higher than traditional gas-discharge bulbs, meaning the overall power consumption required to produce the sun’s irradiance is much lower, and the extra dissipated heat is minimized. With an LED solution, managing the thermal load from the current drivers and power supplies is significantly less challenging for the NASA Goddard facility.

“During the design, [G2V] engineers were very responsive to understanding our requirements and proposing a solution to best meet those requirements while minimizing cost, weight and power.”

Tunable LED drivers to Precisely Match Spectral Response

By using LEDs along with advanced software-control, G2V was able to adjust the output light to better match the exact spectral requirements of the NASA testbed to mimic space (AM0).

“[G2V] developed a system that lets us manipulate and turn off LEDs so we can customize exactly what we want to present as solar light. I think that’s great. With other solar simulators, you turn it on and that’s what you get. [The G2V system] is programmable, and that’s very useful. To me it’s a big step.”

Targeted Spectrum to Reduce Cost and Improve Workplace Safety

LEDs also allowed G2V to build a spectrum that was targeted for the wavelengths of interest to OSAM-1’s visible cameras and sensors, and no more. This reduced overall component number and net cost, not to mention reducing electrical load.

There was an operational benefit of having a more targeted spectrum as well.

“[In the past], in cases where we had radiation, we’d have to put up barriers, which really limits the number of people who can be in the test area.”

With xenon arc lamp solar simulators, their UV emission meant that people could get sunburned by being near the light source. Because their spectrum was fixed (aside from filter adjustments), UV illumination was a constant hazard.

With G2V’s targeted LED spectrum, however, UV emission is no longer a concern. The primary safety concern that remains is eye safety, which means that many people can remain in the same room while only requiring a few curtains and eye protection, thus minimizing the disruption that solar simulation tests have on the cross-functional work in NASA Goddard’s clean room.

“[Here] we’re able to use the G2V solar simulators with safety curtains and people can be in the room. We’re only dealing with the necessary spectrum of light.”

There’s an incredible amount of coordination that must occur for any NASA mission, and being able to remove the need for solar simulator scheduling across teams is a significant benefit.

Delivery and Commissioning

G2V’s LED solar simulators for OSAM-1 have been delivered to NASA Goddard and are awaiting scheduled commissioning in early 2022. In the end, they will have a total of approximately 14 m2 of solar simulator illumination in three light bar arrays.

G2V and NASA are both excited to kick-off solar simulator testing on OSAM-1 after commissioning. It’s expected that the solar simulators will be useful not only for OSAM-1 for the next four years, but for missions into the future. For example, many aspects of NASA’s Artemis program will involve larger-scale, larger-footprint endeavors in both Earth and Lunar orbit, and being able to ground-test maneuvers with a spacecraft-scale solar simulator will be invaluable.

There’s still work ahead for the OSAM-1 mission. Its successful completion will not only mean better curation of our space garbage, but it may also be a stepping stone toward further developments such as large-scale assembly in space, space station assembly, and lunar base assembly, all of which will likely require large-scale solar simulation to rehearse maneuvers and validate instrument performance.

That’s what lies ahead. For now, however, both teams can be proud of the communication, engineering and diligence that culminated in a world-class solar simulator solution for OSAM-1’s unique needs.